Expectations exceeded

Two years ago OptiServe introduced the optical sorting machine Xcalibur. The sorting machine has now found its way all over the world. The way in which the machine scans potato products and ejects them pneumatically from the line is particularly unique. Pomfresh has been using the machine since February 2018.

Xcalibur, OptiServe’s optical sorting machine, has exceeded expectations. Since it was unveiled, the machine has been installed at several large European potato processors. ‘This proves that the market is ready for a new generation of optical sorting,’ says Antoine van Kasteren of OptiServe. He describes the sorting machine as having a number of unique properties. The first point he mentions is its speed. Other machines run at 3 metres per second, but the Xcalibur can reach 5.2 metres per second. ‘This means production and capacity can increase more quickly and the machines can become narrower, which is a real improvement. In addition, the machine is capable of object recognition, which means that the products can be counted inline. After an hour we can see exactly which products have gone past, the number of rejects and the lengths of the products.’

Object sorting

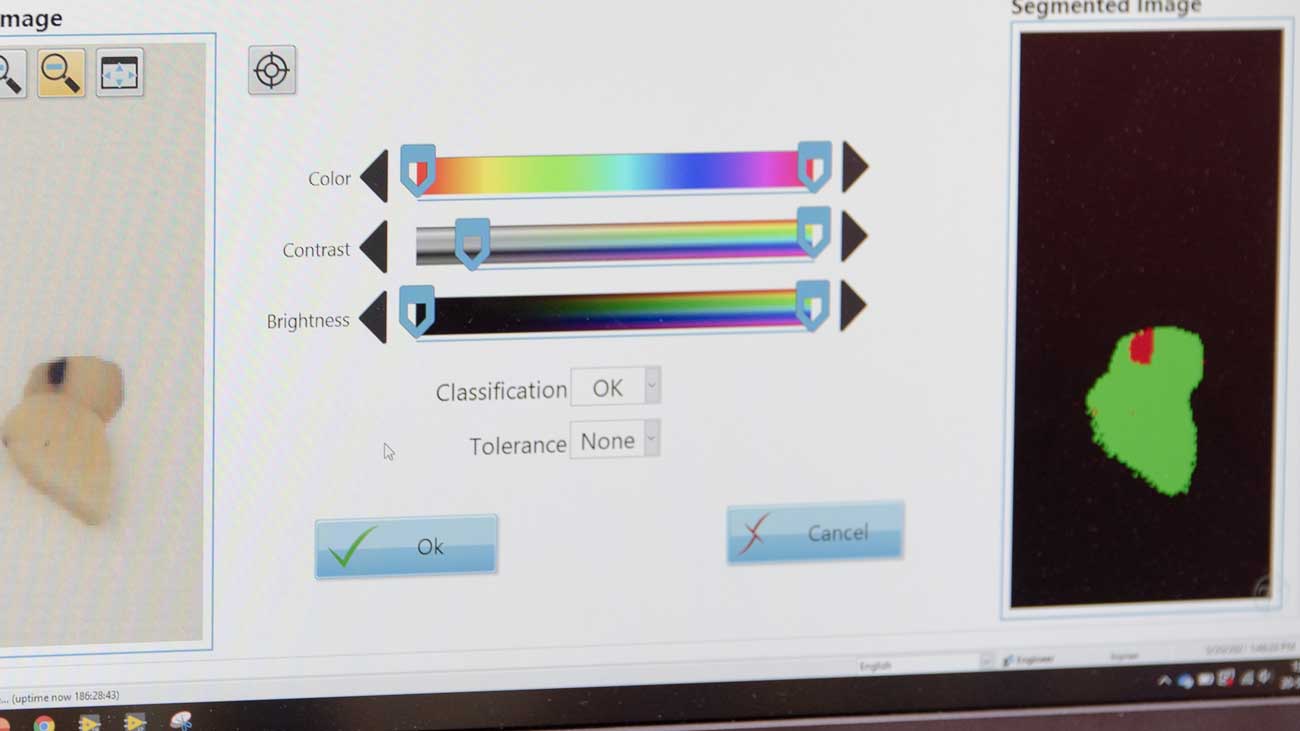

Antoine explains that products are normally sorted on the basis of patches, stripes or spots, whereas object recognition actually shows all the properties of a product, such as length, colour and any defects. The computer system sorts by structure, mass, shape and colour. ‘As a result, you can sort much more extensively and accurately by simply setting this versatile machine according to product type, desired quality and other specific requirements. What we actually do is not reject sorting, but object sorting. It’s also possible to sort and remove items of a certain length for the processing industry, or the good products when the potato stream is of lower quality. That is why we prefer to call the Xcalibur a ‘classifier’ rather than a sorter. Everything is very straightforward, which is good for the sorting quality. In addition, data analysis is becoming increasingly important, and that’s something we can provide better with object recognition.’

‘The rejects are pneumatically ejected using more compact valves with switching speeds of 1 millisecond. The air is directed so accurately and effectively at the object that the effect on “good” products is virtually nil.’

Intelligent pneumatic ejection is unique

In particular, the patented technique by which the Xcalibur scans and pneumatically ejects potato products, ‘intelligent puffing’, is unique. As they pass, the products are imaged with four cameras in combination with the intelligent software, no matter where they are positioned on the conveyor belt. The machine creates realistic images of the potato products, so that it’s also clear exactly where the product is situated. The machine then makes a decision in a fraction of a millisecond: approve or eject. It processes 3,500 to 4,000 objects per second. ‘The rejects are pneumatically ejected using more compact valves with switching speeds of 1 millisecond. The air is directed so accurately and effectively at the object that the effect on “good” products is virtually nil,’ explains Antoine.

The sorting machine can be linked to the entire production line’s data network, so that the different programs can communicate with each other. As a result, the line can be coordinated further to increase the overall yield. With the Xcalibur, OptiServe is mainly focusing on potato processing companies, especially the chips industry. The machine is now working with several products and Antoine is positive about the Xcalibur’s future. ‘The chips industry is still growing. New factories are being built worldwide. In that respect, the whole world is open to us.’ (CH)

SOURCE: AGF PRIMEUR 11 – 2018