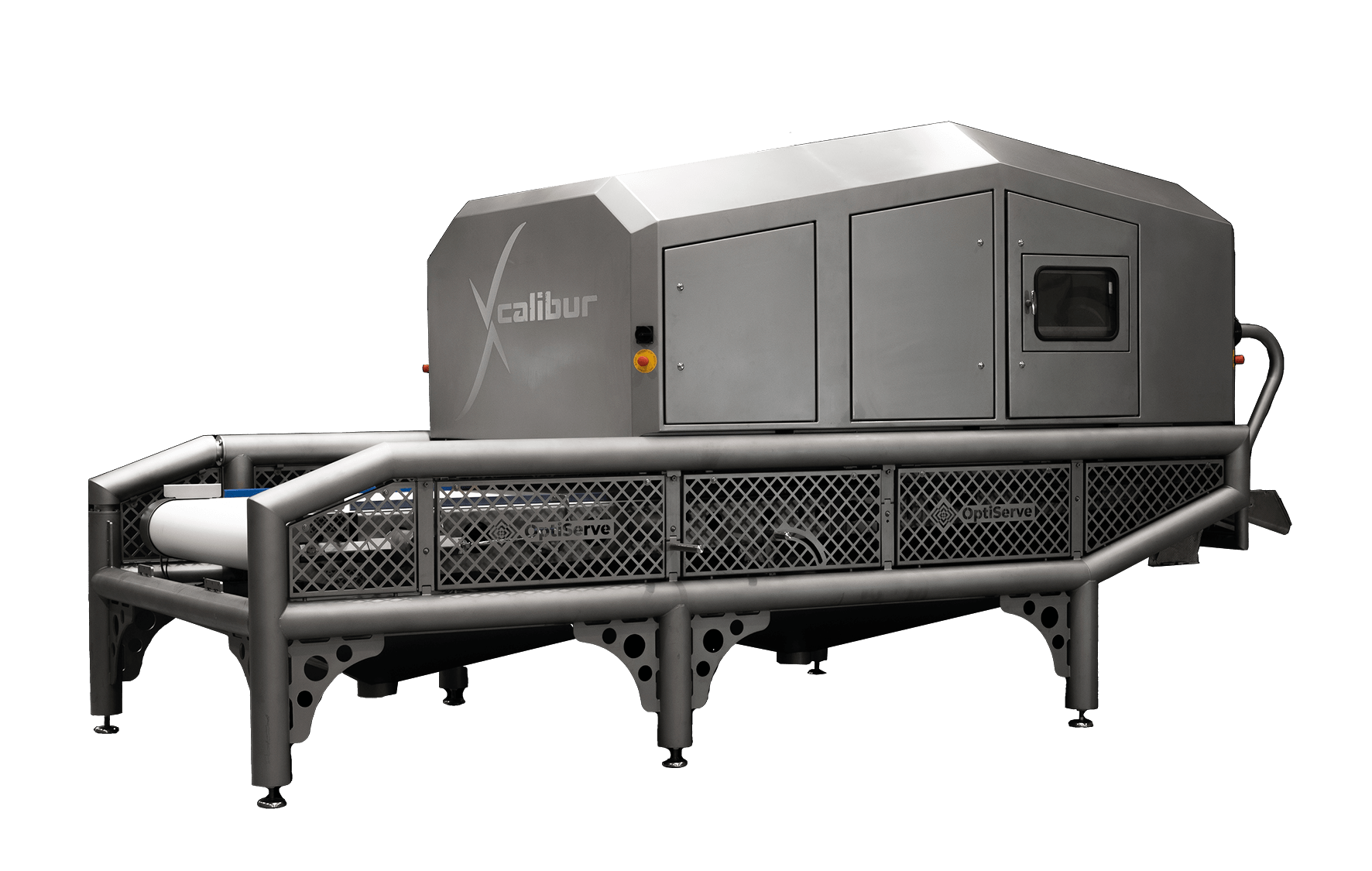

With its advanced optical object recognition, the Xcalibur is one of a kind.

With its advanced optical object recognition, the Xcalibur is one of a kind.

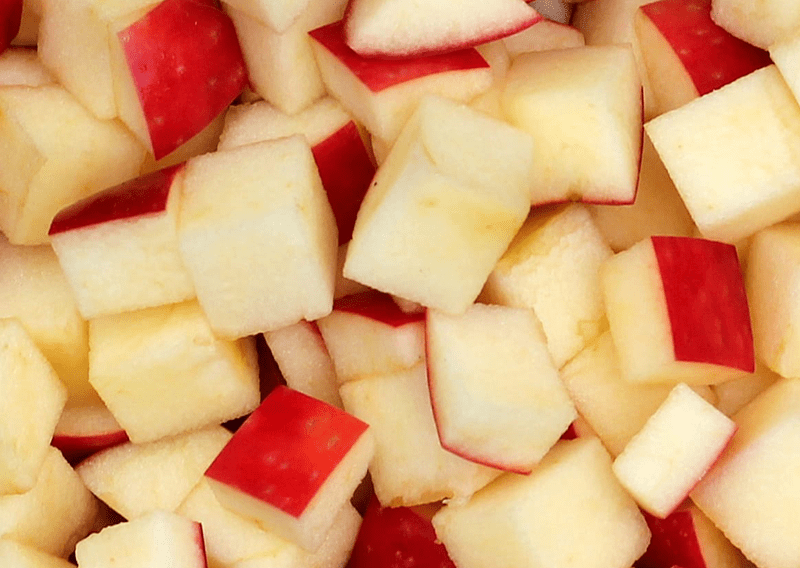

Xcalibur does more than just sort. It classifies. On the basis of colour, length, shape and structure, the Xcalibur can scan and arrange objects and remove them using intelligent pneumatic ejection. And it does so more quickly, carefully and safely than its competitors.

Main features

Watch the Xcalibur video

Xcalibur

Like to see what the Xcalibur can do for your product?

Simplify your production process with the Xcalibur: contact us without obligation for a demo or more information.

Properties

The Xcalibur uses smaller, more directed air pulses that are fully adjusted to the specific object, greatly reducing sorting error.

The smart software systematically scans and sorts the objects. This patented intelligent ejection system ensures that far fewer good products end up in the waste stream.

With its advanced object recognition using the special vision module, the Xcalibur is one of a kind. Xcalibur does more than just sort. It classifies.

The Xcalibur’s detection belt reaches a speed of up to 5.2 m per second.

This increases production capacity and helps with distribution on the belt.

Optionally available with an additional ejection module, enabling a second group of defective products to be pneumatically ejected separately.

In a reverse sorting process in the reject stream, the good products are sorted from the process instead of the defective ones. The defects go straight to the waste stream.

The Xcalibur operates with a lower air pressure and uses directed air pulses lasting just 1-2 milliseconds; as a result, up to 50% less compressed air is used and there is also less noise disturbance.

With this optional module, the user can set how many and what kind of defects the machine should sort.

The detection tunnel can be easily and quickly removed, making maintenance a straightforward task. If the tunnel needs to be cleaned, it can be temporarily replaced with another clean tunnel, avoiding unnecessary production process interruptions.

With a fully automatic and adjustable pneumatic ejection and separation unit you can quickly and easily activate different types of product set-up. The settings, such as belt speed and pneumatic ejection unit, are very easy to change.

The Xcalibur is a robust yet intricate machine; it is fully finished with round materials without any inconvenient protruding parts. This makes it extremely maintenance-friendly.

We detect problems before they even happen. OptiServe keeps an eye on your production process, detecting any problems and making adjustments by means of remote support where possible. Completely remotely.

OptiServe keeps an eye on the production process.

OptiServe detects any technical defects and makes adjustments by means of advanced quality control and visual remote control where possible. Completely remotely. We monitor 24/7 and send real-time feedback so that you almost never have to shut down the production process. This guarantees quality and the targeted production capacity. We see problems before they even happen.

References