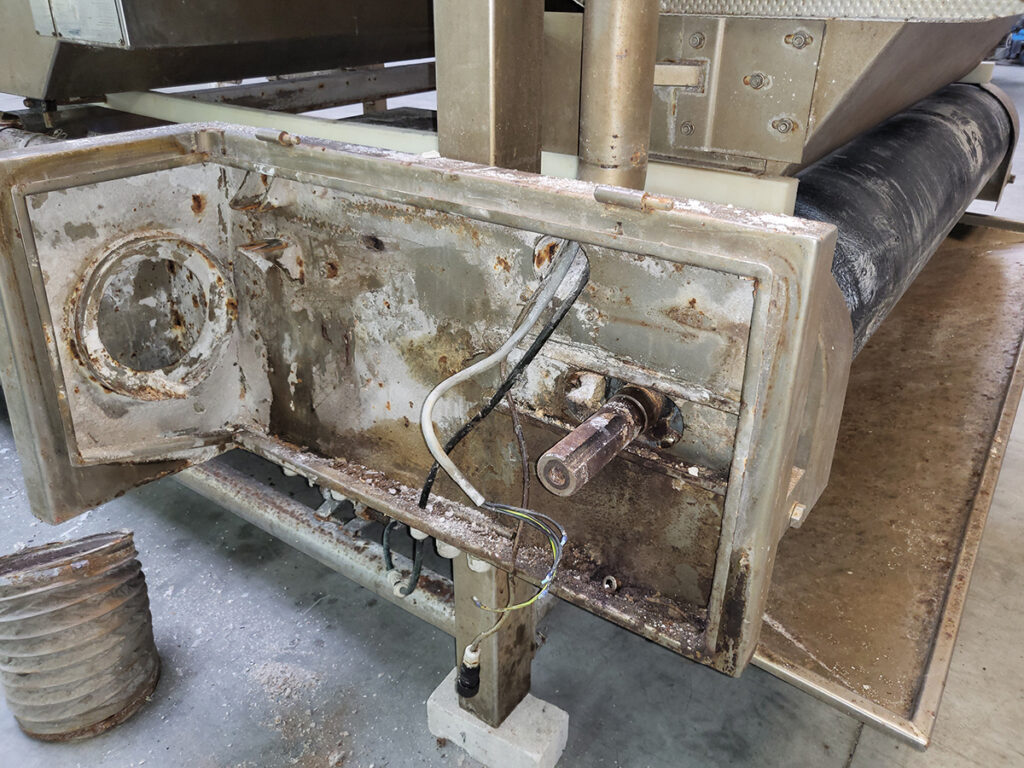

At OptiServe, we thrive on tackling challenges that push our technical know-how and flexibility to the limits. We recently took on an extraordinary project for a salt processing client that required a complete overhaul of an optical sorting machine—a task unlike any we’d faced before. The machine had suffered severe corrosion from salt exposure, presenting us with a novel challenge. This endeavor not only allowed us to showcase our abilities but also fostered a valuable partnership with a promising new talent.

Practical collaboration and growth

A pivotal aspect of this project was its integration with an internship for Teun van Kasteren, a second-year student at Summa Engineering and, incidentally, my son. Teun, together with our seasoned engineer Freek, assumed the mantle of rejuvenating this machine.

Their mission included disassembling the sorting machine, tackling both its mechanical and electrical components. All mechanical parts were meticulously examined and refurbished. The stainless steel frame and panels underwent bead blasting and were carefully polished to regain their original luster.

A thorough technical revamp

On the electronics front, every component, the CPU included, was rigorously tested to ensure functionality. Defective parts were replaced, and all components were cleaned to enhance reliability. The frame was then reassembled using both updated and original mechanical parts. Next, Teun and Freek handled the installation of all electrical and electronic components, upgrading the vision system with state-of-the-art cameras.

The final phase of the overhaul involved precise calibration and configuration of the system, integrating specific UI software to maximize efficiency.

A successful conclusion and commitment to quality

Thanks to the dedication and expertise of Teun, Freek, and the entire OptiServe team, the optical sorting machine was completely restored. Pending approval from his mentor, Teun is set to install the machine in May, marking the successful conclusion of both a complex overhaul and his internship project.

This project reaffirms OptiServe’s commitment to innovation, collaboration, and the highest standards of quality. The successful restoration of the optical sorting machine exemplifies our ability to tackle complex challenges through passion, expertise, and teamwork.

Sustainable sorting with OptiServe

OptiServe’s E-Select program merges sustainability with innovation by offering high-quality, refurbished sorting machines tailored to various industries and budgets. This initiative underscores our expertise in extending the lifespan of machinery, providing customers with cost-effective options for their sorting needs, from food products to other applications.